3D Interferometric-Sensors

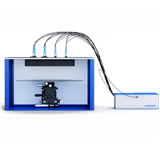

nXP-1

One-shot Interferometer Sensor

High-speed measurement of shape

and warpage with one image

and warpage with one image

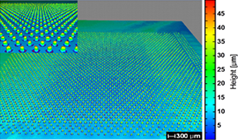

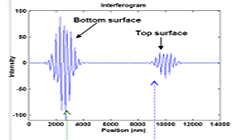

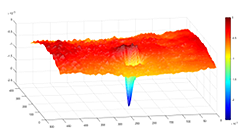

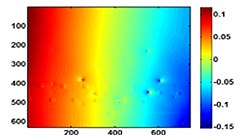

nXP-1 measures & inspects the surface shape of reflective materials

with one image. Since the product’s surface measures with one image,

it can be implemented on the fly, enabling quick measurement of large areas.

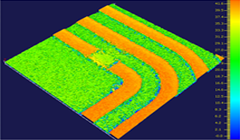

It is possible to inspect and measure surface defects of products

that are generally difficult to measure, such as defects on the surface

of wafer chips larger than several ㎚, warpage of camera film,

and bubble measurement on transparent surfaces. nXP-1 can also customise according to the size or shape of the product

to be measured and the specifications desired by customers.

This product is equipped with inspection and measurement solutions

to ensure the perfect quality of the mass production line.

with one image. Since the product’s surface measures with one image,

it can be implemented on the fly, enabling quick measurement of large areas.

It is possible to inspect and measure surface defects of products

that are generally difficult to measure, such as defects on the surface

of wafer chips larger than several ㎚, warpage of camera film,

and bubble measurement on transparent surfaces. nXP-1 can also customise according to the size or shape of the product

to be measured and the specifications desired by customers.

This product is equipped with inspection and measurement solutions

to ensure the perfect quality of the mass production line.

Key Features

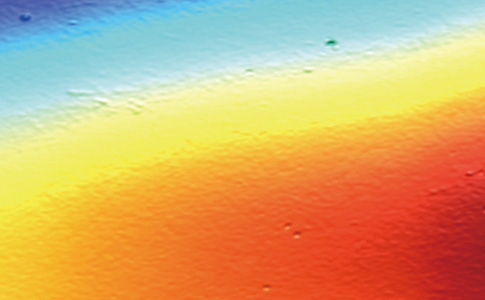

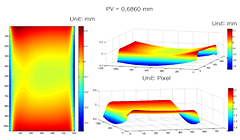

· Measure the surface shape

of wafer and film types

with just one image

of wafer and film types

with just one image

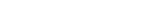

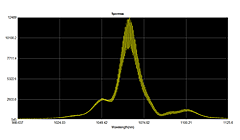

· Bubble measurement

on transparent surfaces

on transparent surfaces

· Applicable to the mass production line

· Fast measuring

and data acquisition

and data acquisition

APPLICATIONS

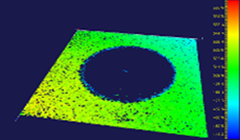

Bubble

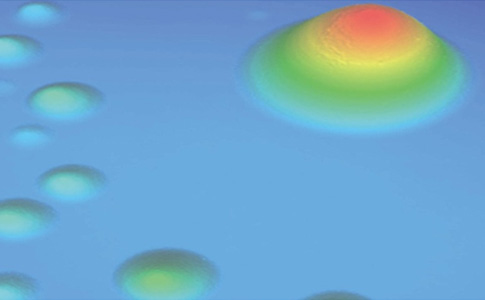

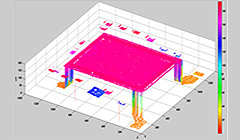

Film

IR film

Chip warpage

Specifications

Request a specification

Contact us

Latest News

Request a sample test

Request a sample test now!

You can experience the technology of Nexensor.

You can experience the technology of Nexensor.

Contact us

| Measuring model | Measuring technology | Test content | Measuring data |

|

Large-area measurement with WSI interferometers FOV extensive application | Micro Bump Height Monolayer membrane thickness measurement PCB fine pattern Processed surface roughness measurement Sensor step-difference measurement |

|

|

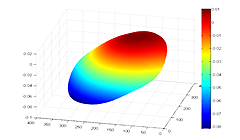

Free-Form Metrology

Divided inspection possible according to product curve angels

|

Inspection of lens and glass, and measurement of shapes

Inspection of OLED surfaces, and measurement of shapes

Inspection of wafer surfaces, and measurement of shapes

|

|

|

Real-time measurement of transparent and semitransparent product thickness

Applicable to multi-channels

|

Measurement of wafer(silicone, sapphire) thickness

Measurement of glass and film thickness

|

|