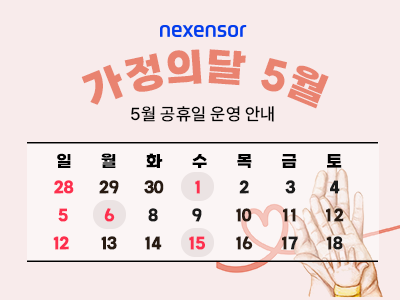

3D Free-Form Measuring

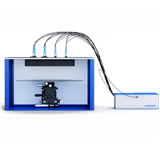

nXF-3

Freeform surface

measuring system

measuring system

3D surface shape measurement of products

with various curved & specular/rough surfaces

with various curved & specular/rough surfaces

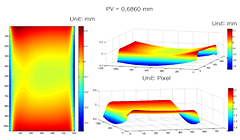

nXF-3 is the world’s first product to measure the warp & bow

of highly reflective or transparent products such as wafers

and films by applying ‘deflectometry’. By providing quantitative and accurate measurement values

as well as the surface shape of products, it improves process stabilization

and efficiency. In addition, it can measure and inspect the surface shape of

various specular materials to measure warpage and dents on the film surface,

secondary battery pouch, hydrogen battery thin plate, automobile paint,

and so on, with high reliability.

of highly reflective or transparent products such as wafers

and films by applying ‘deflectometry’. By providing quantitative and accurate measurement values

as well as the surface shape of products, it improves process stabilization

and efficiency. In addition, it can measure and inspect the surface shape of

various specular materials to measure warpage and dents on the film surface,

secondary battery pouch, hydrogen battery thin plate, automobile paint,

and so on, with high reliability.

Key Features

· Inspection of shiny

or transparent product surfaces

· Various FOVs applied

or transparent product surfaces

· Various FOVs applied

· Applicable to the mass production line

· High precision

· High precision

· Simple measuring process

· Various data analysis

· Easy user interface

· Various data analysis

· Easy user interface

Application

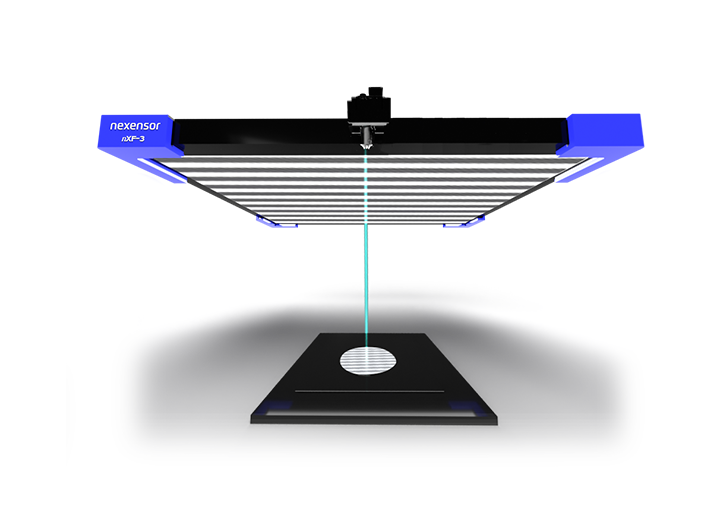

The world’s first wafer

hard face/rough face.

development of simultaneous

measurement technology.

hard face/rough face.

development of simultaneous

measurement technology.

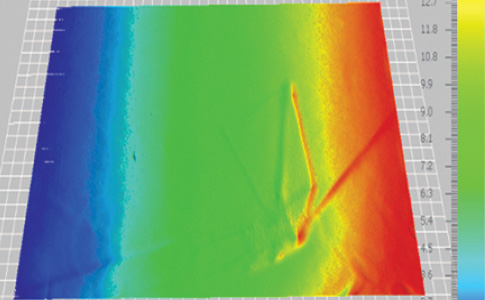

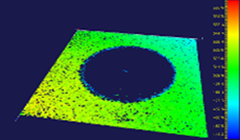

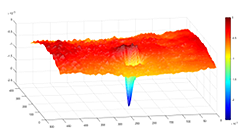

Wheel Mark

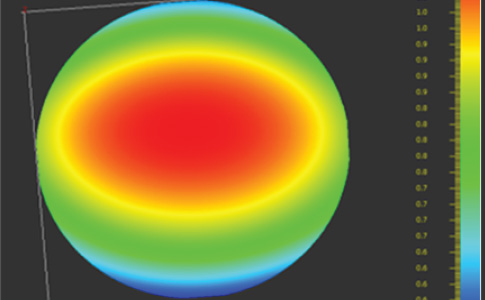

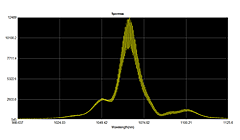

Wafer Warpage

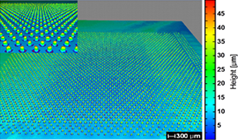

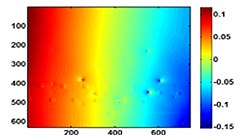

Battery

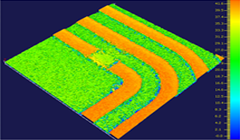

Automotive

Specifications

Request a specification

Contact us

Latest News

Request a sample test

Request a sample test now!

You can experience the technology of Nexensor.

You can experience the technology of Nexensor.

Contact us

| Measuring model | Measuring technology | Test content | Measuring data |

|

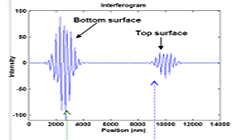

Large-area measurement with WSI interferometers FOV extensive application | Micro Bump Height Monolayer membrane thickness measurement PCB fine pattern Processed surface roughness measurement Sensor step-difference measurement |

|

|

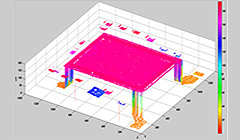

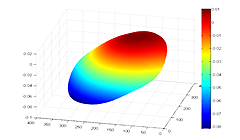

Free-Form Metrology

Divided inspection possible according to product curve angels

|

Inspection of lens and glass, and measurement of shapes

Inspection of OLED surfaces, and measurement of shapes

Inspection of wafer surfaces, and measurement of shapes

|

|

|

Real-time measurement of transparent and semitransparent product thickness

Applicable to multi-channels

|

Measurement of wafer(silicone, sapphire) thickness

Measurement of glass and film thickness

|

|